Rollers for roughing stands need to combine some characteristics, some of which will counteract each other, including wear resistance, heat crack resistance, impact resistance, thermal hardness, and thermal strength. The network carbide can improve the wear resistance and impact resistance. However, if the content of network carbide is too much, the fracture toughness will be seriously reduced. This will promote the formation of hot cracks in rough rolling. In order to reduce the influence of excessive carbides and maintain wear resistance, alloy elements such as nickel and molybdenum should be added to make the matrix form bainite/martensite(acicular), which is more wear-resistant than ordinary pearlite matrix. Molybdenum also helps to improve the high-temperature hardness of rolls.

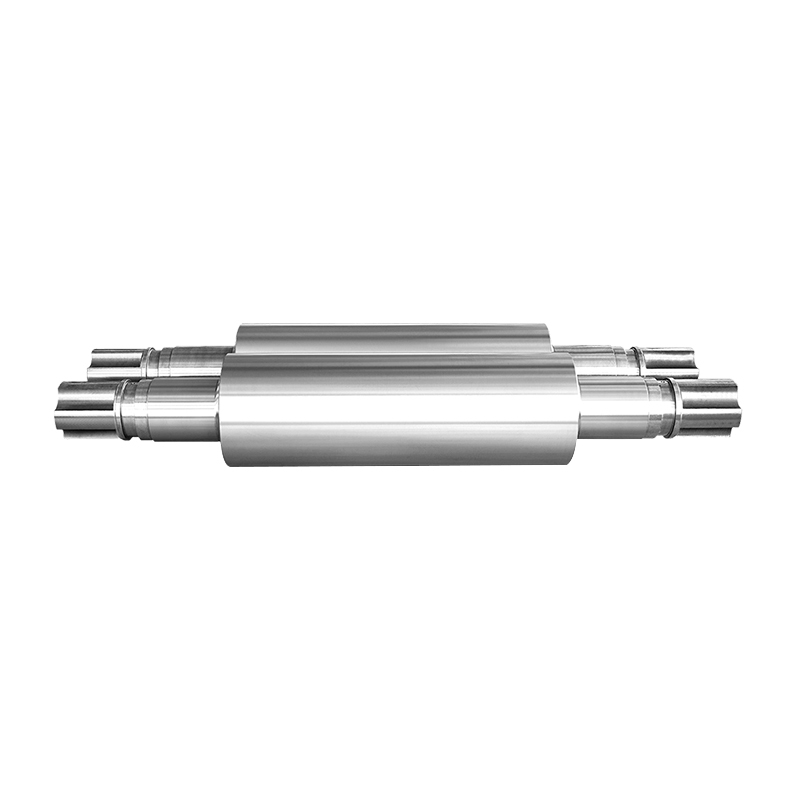

NCC roll is made of high alloy materials and special heat treatment. The content of carbide in the matrix is less than 5%, which meets the requirements of a roughing mill stand.

English

English русский

русский