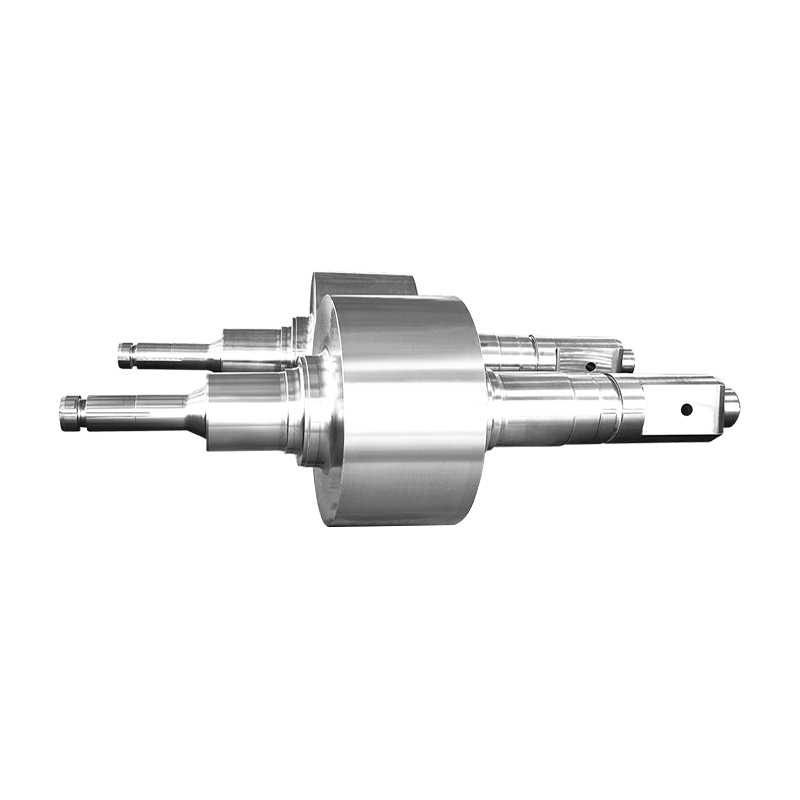

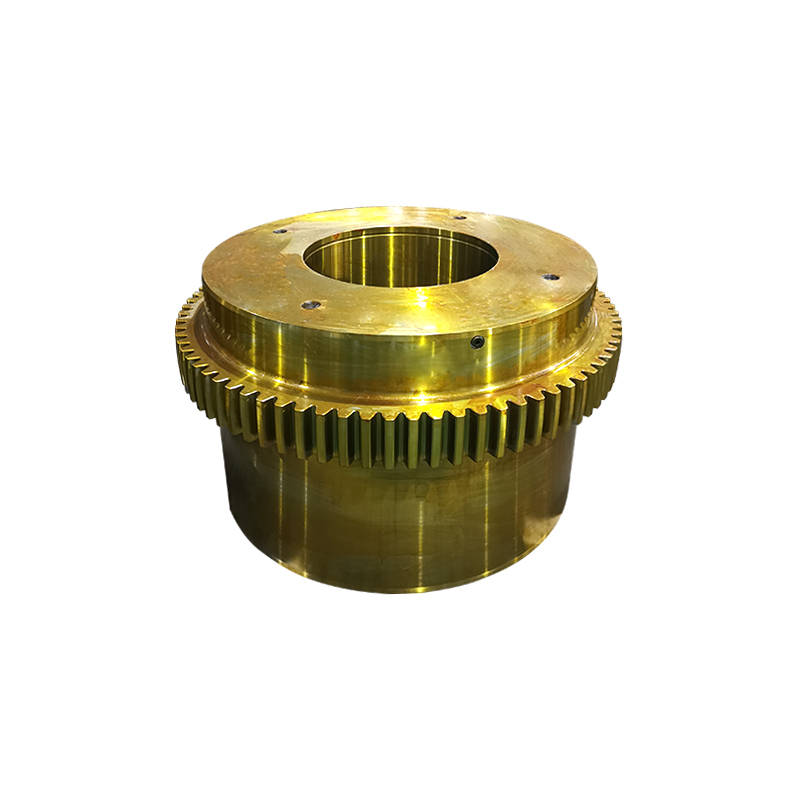

The edging roll is the main spare part of the universal unit to ensure the width and flange surface quality. The edging roll is required to have a higher hardness and a smaller hardness drop. Different materials and hardness can be selected for different specifications of section steel edging rolls.

Edge rolls are a special type of roll used to process the edges of metal strips or plates during the rolling process. The design and use of edge rolls can improve the quality and precision of rolled products while reducing material waste. Edge rolls are used to control the edge shape and size of metal strips or plates to ensure that the products meet specific specifications. By using edge rolls, the dimensional accuracy and surface quality of rolled products can be improved. Precise edge control can reduce scrap caused by edge defects and improve production efficiency. Edge rolls usually have special structural designs, such as tapered, curved, or adjustable edge shapes, to suit different rolling requirements. Edge rolls usually need to be heat treated to improve their hardness, wear resistance, and impact resistance.

English

English русский

русский