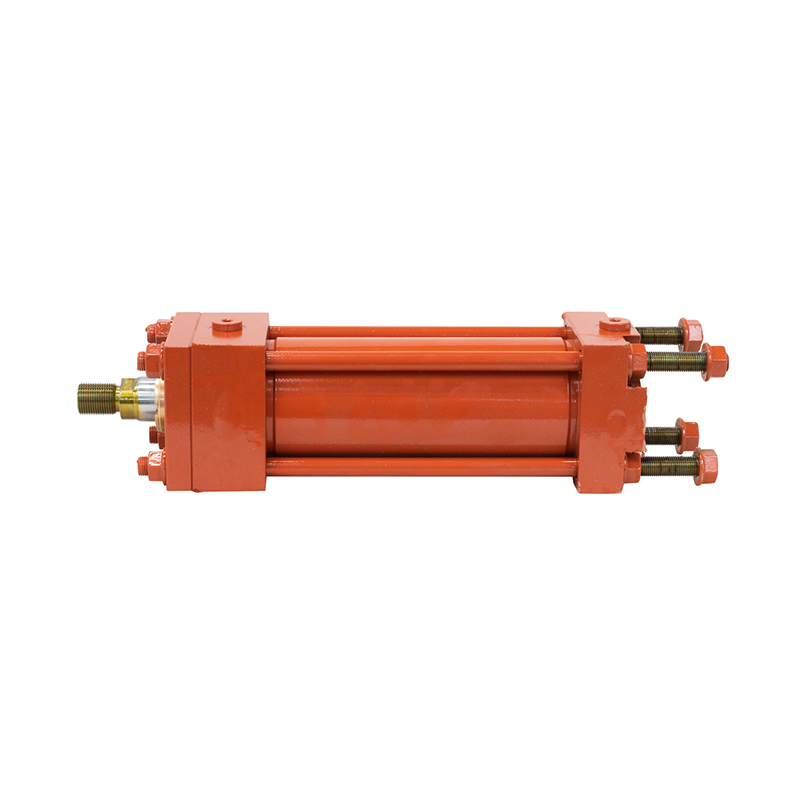

The performance of the graphite steel roller is similar to that of the semi-steel roller, and its biggest feature is that there is a small amount of fine spherical graphite in the structure. It can improve the resistance to hot cracking and the adhesion of oxidation resistant iron sheet of the roll and has low requirements for water cooling conditions. It is mainly applicable to the roughing and blooming stands of the section mill.

Graphite steel rolls are a special type of roll that has graphite particles added to a steel matrix. This combination of materials offers some unique properties and advantages for specific industrial applications. Graphite is a good lubricant, so graphite steel rolls have a lower coefficient of friction during the rolling process, helping to reduce wear and improve rolling efficiency. Graphite has good thermal conductivity, which helps the rolls dissipate heat quickly at high temperatures and reduce thermal deformation. Graphite steel rolls have better corrosion resistance than ordinary steel rolls, especially in certain chemical processing environments. The addition of graphite can improve the shock-absorbing properties of the rolls, helping to reduce vibration and noise. Graphite steel rolls may be easier to process and manufacture than some hard materials.

English

English русский

русский