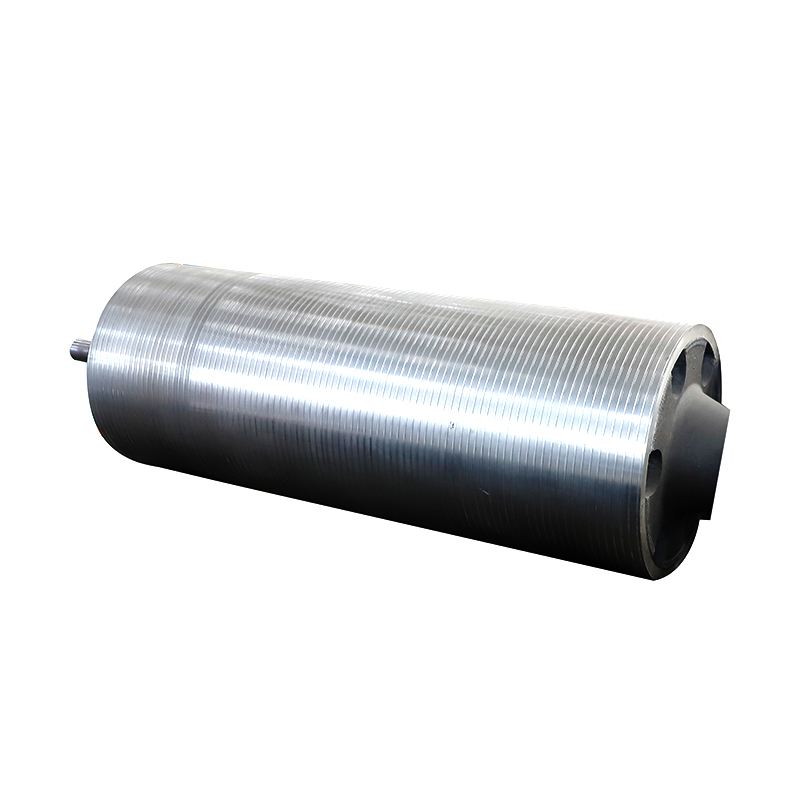

The sinking roller is a piece of equipment commonly used in the steel smelting process. It is mainly used to control the temperature and shape of the steel billet to ensure the quality and performance of the steel billet. Its working principle is that after the steel billet is taken out of the furnace, it is fed into the sinking roller through a series of rollers and rollers. High-pressure water flow is injected into the sinking roller to rapidly cool the surface of the steel billet, thereby controlling the temperature and shape of the steel billet. In the field of steel processing, sunk rollers can be used in rolling, drawing, extrusion, and other processes to control the temperature and shape of metal materials, thereby improving product quality and performance.

English

English русский

русский